Industrial Hot Air Generators for Efficient Natural Fiber Drying

When working with natural fibers like cotton, hemp, or jute, proper drying is essential to maintain quality and ensure smooth production. Industrial Hot Air Generators (IHAGs) are the ideal solution for this process, offering reliable, controlled heat to dry fibers efficiently and consistently. At GV Industrial Heaters, we provide top-quality IHAGs designed to meet the demands of industries that rely on precise drying solutions.

What is an Industrial Hot Air Generator?

An industrial hot air generator is a heating system that produces hot air to dry materials quickly and efficiently. It’s particularly useful in industries such as textiles, agriculture, and manufacturing where drying large volumes of material, like natural fibers, is necessary.

Why Hot Air Generators are Essential for Drying Natural Fibers

Natural fibers absorb moisture from their surroundings, making it essential to dry them properly before they can be processed further. Moisture content in fibers can lead to a decrease in quality, delayed processing, and even fungal growth. Here’s where hot air generators come into play:

-

Consistent Heat Distribution: Our hot air generators ensure that heat is evenly distributed throughout the drying chamber, allowing fibers to dry uniformly.

-

Energy Efficiency: With optimized energy consumption, our generators reduce operating costs while delivering the required heat output, making them highly efficient for large-scale fiber processing.

-

Customizable Temperature Control: Different fibers have unique drying needs. Our IHAGs are equipped with precise temperature control, ensuring you can fine-tune the heat output based on the fiber type and moisture level.

-

High Capacity and Continuous Operation: The industrial hot air generators are built to handle large batches of natural fibers and can operate continuously without the risk of overheating or wear, making them ideal for industrial-scale drying operations.

Key Features of GV Industrial Hot Air Generators

-

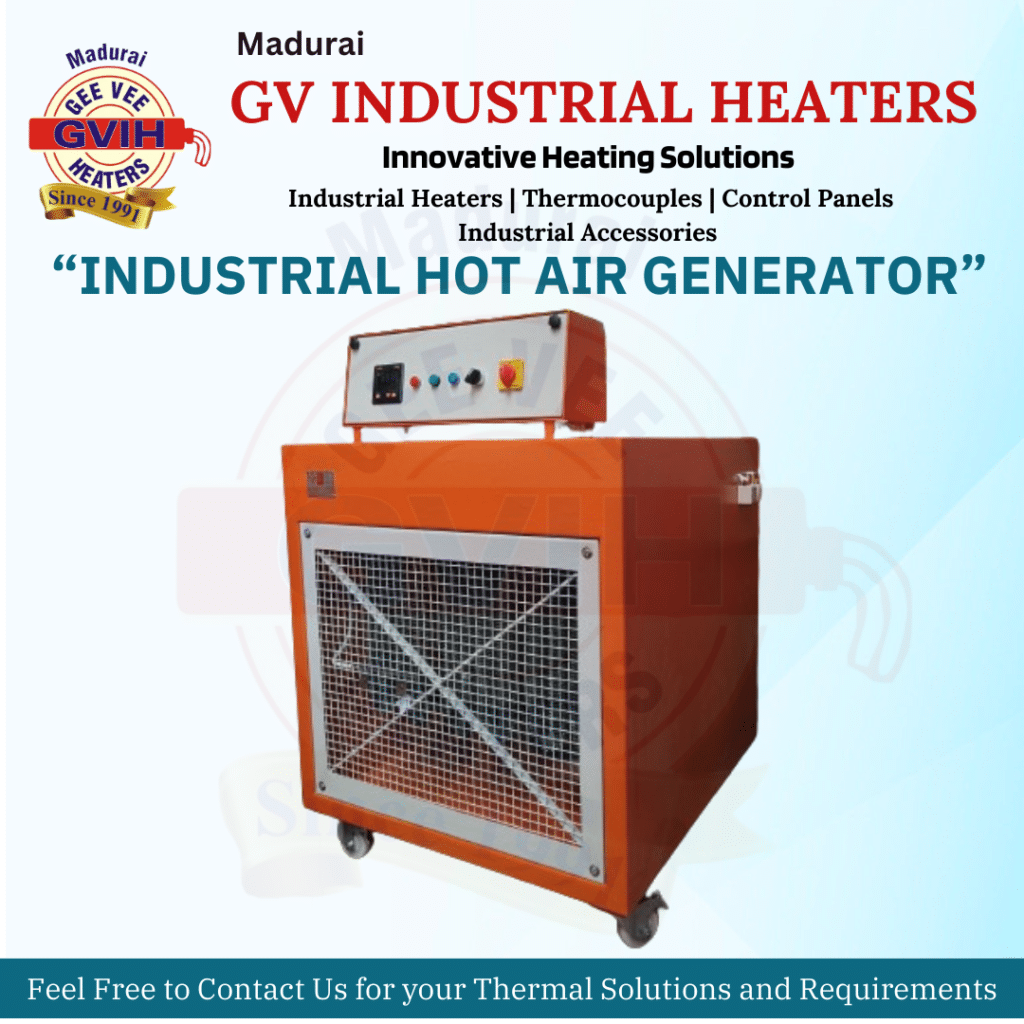

Robust Design: Our generators are constructed using durable materials, ensuring longevity and low maintenance even under continuous industrial use.

-

Portable and Compact: Designed with mobility in mind, our generators can be easily moved across your workspace for flexible operation. Despite their compact design, they offer powerful performance.

-

Advanced Control Panels: Featuring intuitive control panels, our hot air generators allow easy monitoring and adjustments of temperature and airflow, giving operators full control over the drying process.

-

Safety and Compliance: At GV Industrial Heaters, safety is a top priority. Our hot air generators are designed with multiple safety features, including overheat protection, ensuring compliance with industrial safety standards.

Applications in Natural Fiber Drying

The use of hot air generators for drying natural fibers brings numerous benefits across various industries:

-

-

Textile Industry: Whether it’s cotton or wool, natural fibers require careful drying to maintain their quality. Our IHAGs provide the optimal conditions for drying large volumes of fibers while preserving their natural properties.

-

Agriculture and Eco-Friendly Products: For industries working with fibers such as hemp or flax, which are often used in eco-friendly products, controlled drying ensures these materials remain strong and durable for further processing.

-

Composite Materials: Natural fibers are increasingly used in composite materials due to their sustainability. Proper drying is critical to ensuring their performance in applications such as automotive parts and building materials.

-

Conclusion

At GV Industrial Heaters, we understand the importance of efficient fiber drying in your industry. Our Industrial Hot Air Generators provide reliable and energy-efficient solutions tailored to your needs, helping you improve productivity while reducing costs.

For more information on how our IHAGs can benefit your business, contact us today.